Cool tool ii is a universal cutting and tapping fluid that performs extremely well on all metals including aluminum stainless steel exotic alloys and some plastics.

Metal cutting fluid bacteria test kit.

1 x refractometer 0 32 brix optional can be added to the kit if you wish to purchase one don t already have one.

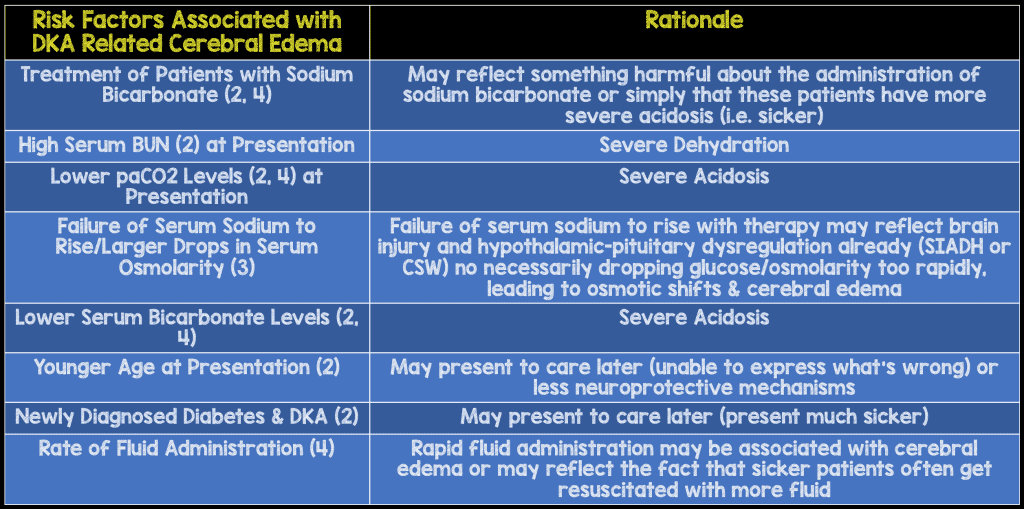

10 4 to 10 6 cfu ml reasonable control.

Dipslides mbc control.

The simple common sense program of testing filtering removing tramp oil and using the biotech non biocidal stabilizer for metalworking fluids has allowed some customers to avoid wholesale disposal of their fluids for over 10 years.

Coolant test kit for metalworking fluid test f737 everything the metalworking fluid professional would.

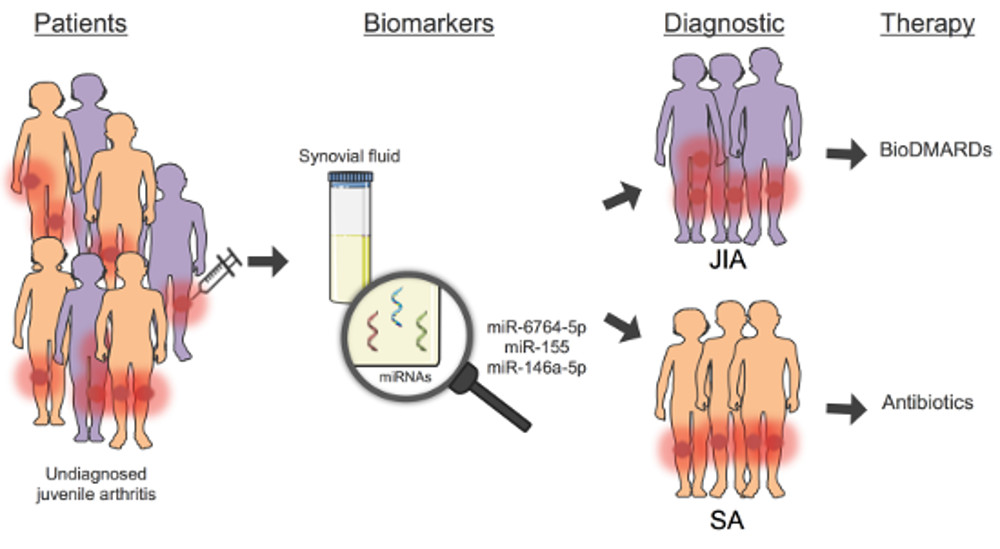

Uncontrolled development of bacteria in metalworking fluids presents a serious risk due to the spray mist.

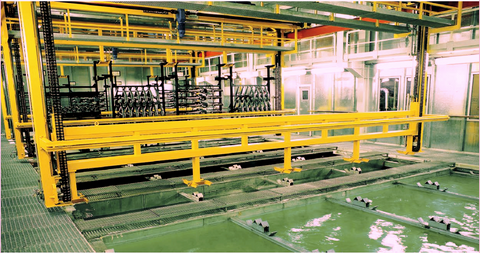

Our bacteria testing fluid management expertise is built from a background in managing industrial cutting fluids within the aerospace and automotive sectors.

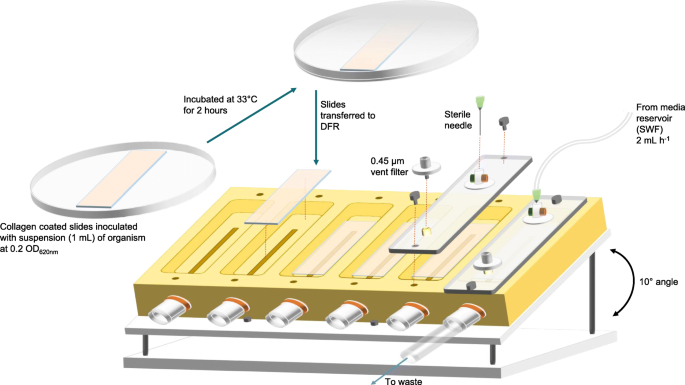

Also suitable for coolant bacteria testing these dipslides come with the following benefits.

Srb sulphite reducing bacteria these bacteria exist when the oil is stagnant such as metalworking sumps or oil sto.

Ip test pera.

Fluid replacing in the tube.

1 x orion mx8 dipslide incubator up to 8 dipslide capacity 2 x boxes of metal cutting fluid dipslides bacteria yeast mould test 20 dipslides in total.

Pack of 10 included in our bacteria test kit.

The metal cutting fluid dipslides mcbtm2 dipslides test the cutting fluid for bacteria and yeasts moulds.

These cutting fluid dipslides offer a convenient total viable bacteria test count as well as yeasts moulds and fungi in a single dual sided test.

Bacteria are being maintained at low levels.

Keep your metal working fluids machining coolant working efficiently with our rapid bacterial testing kit.

Fluid solve ltd have more than fifty years combined experience of working in the industrial metalworking fluids industry.

Sampling testing notes for metalworking cutting fluids delivering simplicity and affordability through innovation.

Regular checks and actions to maintain the fluid quality should continue.

View details if you want to identify microbial contamination in your systems with an easy to use test method please contact mce inc.

Review and take action to check the quality of the metalworking fluid and adjust fluid parameters to those recommended by the supplier.

It may cause equipment malfunction off odors degradation in the fluid quality economic losses and finally they pose as a major health hazard.

High levels of bacterial contamination will degrade the quality of the fluid and will become a health risk.

1 prior to use please keep the.

Several gram ve and gram ve bacteria are found as contaminants.

3 place the slide into the incuba tor for the.

Regular microbiological testing of metal cutting fluids is very important.